Multi-Tasking Machine Reduces Downtime Manufacturing Carbon Fiber Components for Railway and Energy Applications

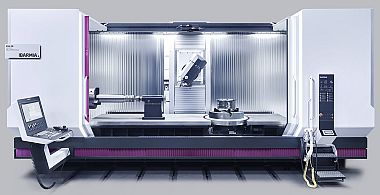

Ibarmia's ZVH 60/L4000 MULTIPROCESS has been designed for machining applications in carbon fiber intended for the railway and energy sectors.

It stands out for its generous working space (X 4000 / Y 1100 / Z 1300), a special fixed table with a vacuum clamping system, and all the advantages of integrating horizontal and vertical turning capacity (with swings of up to ø1500 mm) in the same 5-axis multitasking machine, drastically reducing downtime and enabling the handling of a wide range of applications.

The continuous B-axis head with torque motor houses a powerful spindle of up to 84 kW and 12,000 rpm and is equipped with preparation to accommodate a special cutting tool for horizontal turning operations.

Given the material requirements, the model incorporates a series of additional protection measures such as total encapsulation of the machine, protective bellows for linear guides and ball screws, a specific dust extraction system, or overpressure measures for the electrical cabinet, etc.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::